SERVICES

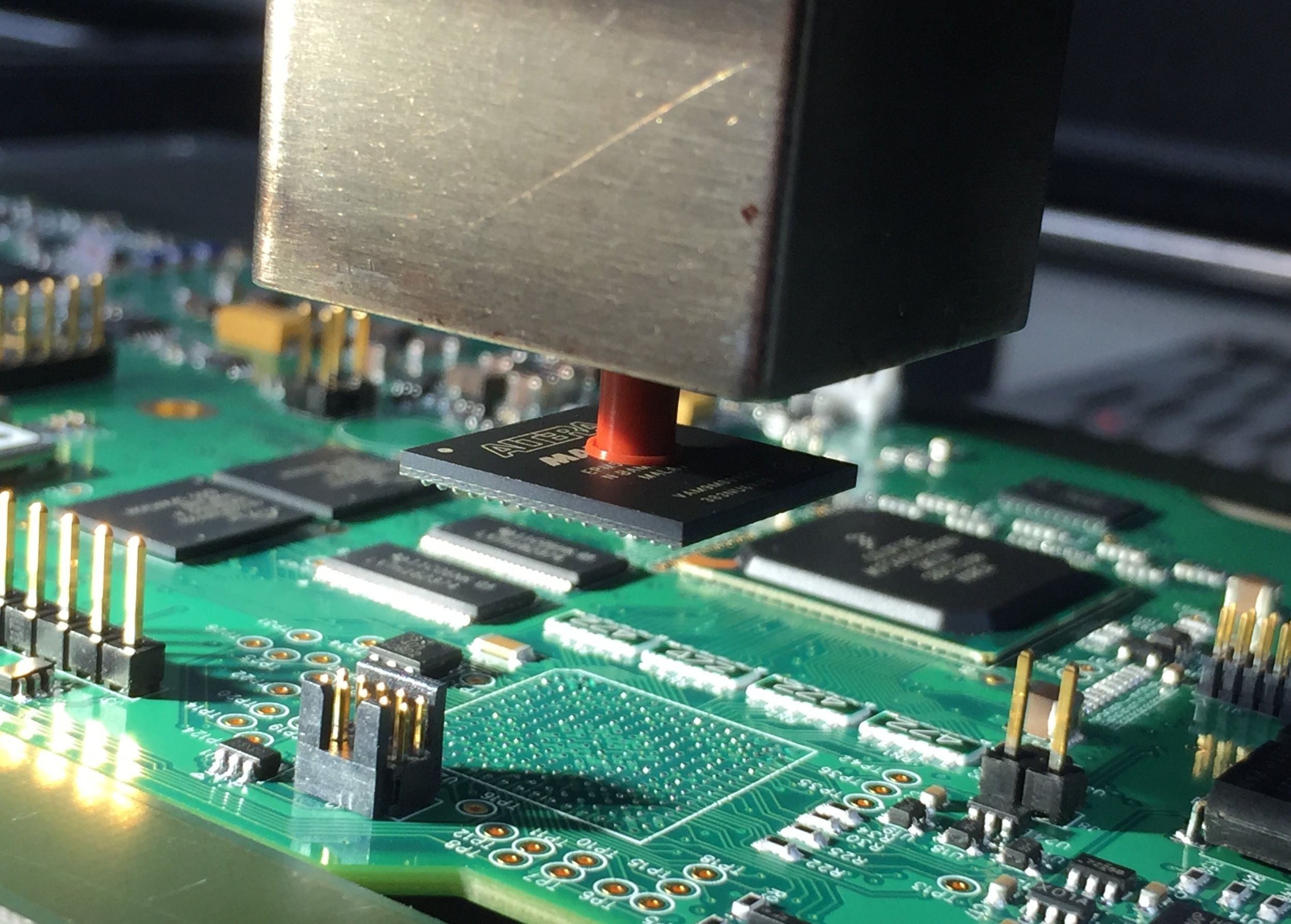

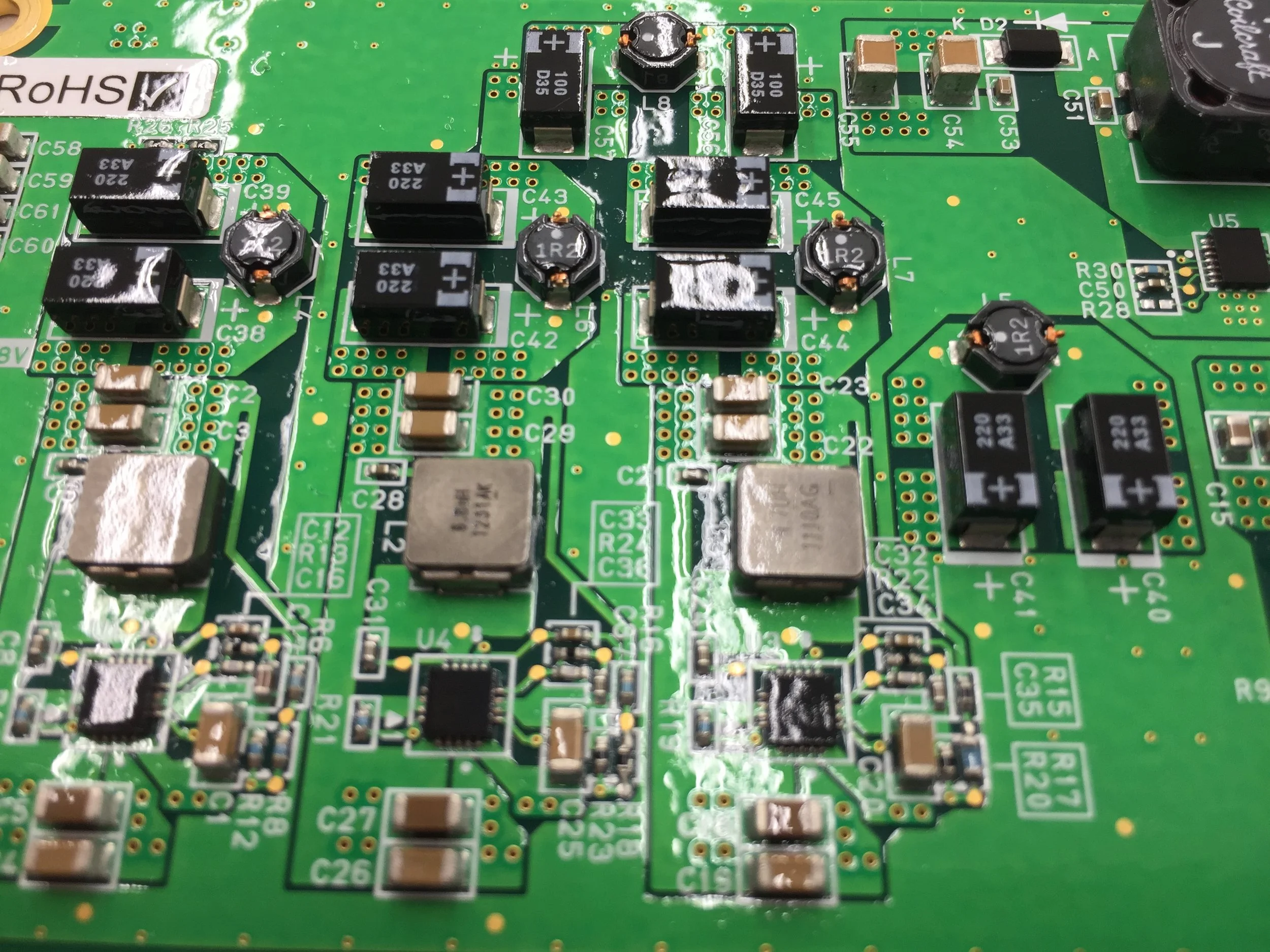

Printed Circuits Assembly Corporation is a contract electronics manufacturer of simple to highly-complex boards. Our versatility of services and expertise allows us to serve all types of clients – from medical, technical, and aerospace, to personal innovation projects. We build for prototypes with a quantity as low as one, to large scale production runs.

We don’t just build boards; our experienced team can provide insight and feedback for improvements to your product, efficiency, and cost.